As leaders in the keyboard refurbishment industry since 2012, we’ve revolutionized the process with innovations like SticKeys™ and True Backlit SticKeys™. These advancements address inefficiencies in traditional keyboard printing and redefine what’s possible in refurbishment. Let’s compare the old and the new, examining their cost, time, and sustainability impacts.

Standard Keyboard Printing vs. SticKeys™

The Traditional Process:

- Complexity: Printing requires disassembling the keyboard. For devices like Apple MacBooks, this involves removing over 50 screws and poses a high risk of shorting out the motherboard if the battery isn’t disconnected.

- Time-Consuming: Removing and replacing the lid takes 40 minutes, and printing takes an additional 10 minutes per keyboard.

- Costly and Centralized: We charge £20 for the service, but laptops must be shipped to a central location equipped with £30,000 printers, adding transportation costs and delays.

The SticKeys™ Revolution:

- Ease of Application: SticKeys™ require no disassembly. They are applied directly to the keyboard, saving significant time.

- Global Scalability: At just £5 each, SticKeys™ can be produced at scale (up to 5,000 per day) and shipped anywhere for local application. This aligns with our motto: "Think Global, Refurbish Local".

- Sustainability: Eliminating the need for extensive equipment and transportation significantly reduces carbon footprints.

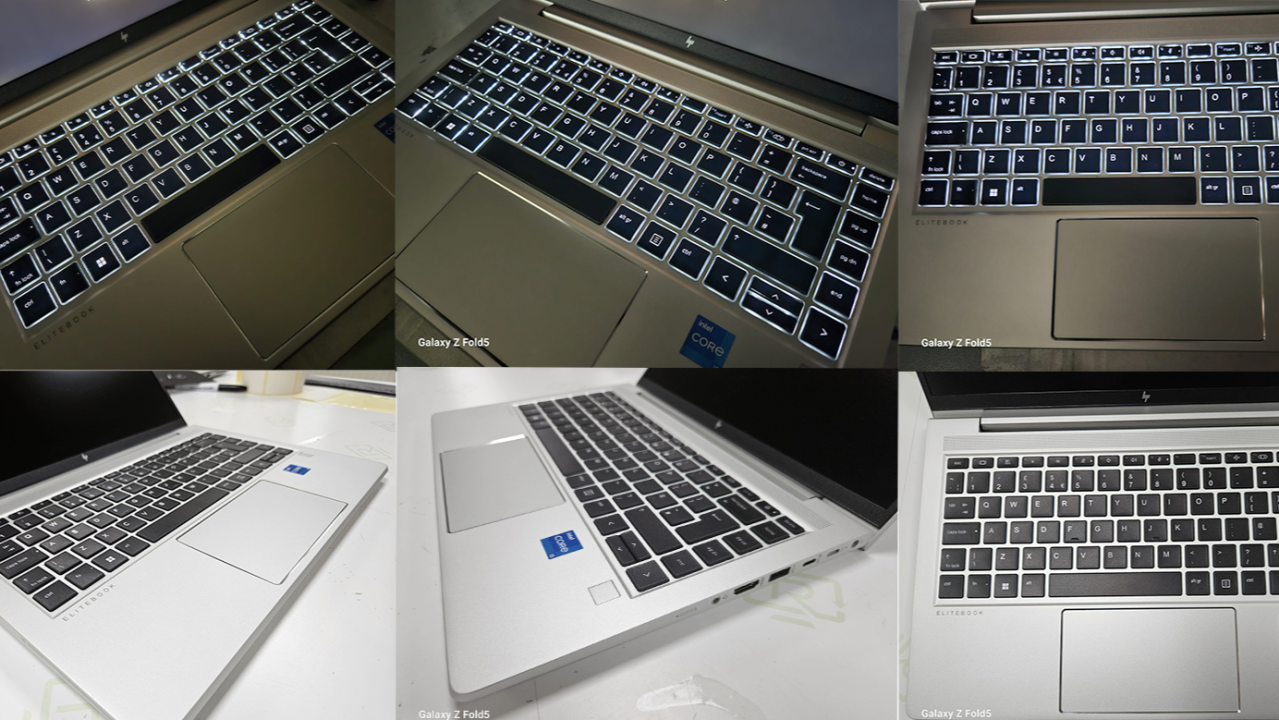

True Backlit Keyboard Printing vs. True Backlit SticKeys™

Traditional Backlit Printing:

- Time-Intensive: Beyond disassembly, laser etching and printing take over an hour. Any mistake in this one-shot process is costly and hard to fix.

- Limited Flexibility: Updating a keyboard (e.g., for language changes) requires repeating the entire process, adding further costs and time.

True Backlit SticKeys™:

- Streamlined Process: By eliminating the need for disassembly, laser etching takes only 10–15 minutes. SticKeys™ application adds just 3 minutes, bringing the total process to 15 minutes.

- Easy Updates: SticKeys™ can be removed and replaced to accommodate new languages or requirements without re-laser etching, promoting reusability and circularity.

- Cost-Effective: The cost remains low at £5 per set, and localized production minimizes the environmental impact.

Why SticKeys™ Are the Future

- Cost Efficiency: SticKeys™ cost less than half of traditional printing processes.

- Time Savings: Application takes less than a quarter of the time required for traditional methods.

- Sustainability: SticKeys™ contribute to a circular economy, allowing keyboards to be reused repeatedly.

- Global Accessibility: Without the need for specialized equipment, SticKeys™ democratize refurbishment, enabling local application worldwide.

Conclusion

SticKeys™ and True Backlit SticKeys™ are transforming keyboard refurbishment, offering faster, more affordable, and sustainable solutions. They align with the growing demand for environmentally responsible practices while maintaining premium quality.

If you’re ready to revolutionize your refurbishment process, contact us to explore the potential of SticKeys™. Together, we can redefine refurbishment for a greener, more efficient future.

As with all our products they come with a 3 year from peeling or fading warranty which none of our customers have ever had to utilise.

#therefurbcompany #thinkglobalrefurbishlocal #innovation #patentpending #stickeys #truebacklitstickeys #designedintheuk #madeintheuk #remadeintheuk #circularproduct