The IT refurbishment industry has grown rapidly over the last decade, but despite the progress, we still lack a widely accepted, practical, and measurable standard for how refurbished devices should be prepared, tested, and delivered.

After years of hands-on experience in this field—from wiping and reloading to cosmetic repairs, testing, and parts harvesting—I’ve drafted a proposed standard that aims to bring more consistency, quality, and sustainability into our practices. This is not final, and it’s not perfect—but it’s a starting point.

The goal is simple: to open up the conversation, invite feedback from others in the industry, and move toward a shared benchmark that raises the bar for everyone—from technicians and resellers to customers and planet-conscious operators.

👇 Below is the first full draft of the Refurbishment Standard for IT Equipment. I’d love your feedback, criticisms, and suggestions. Let’s build this together.

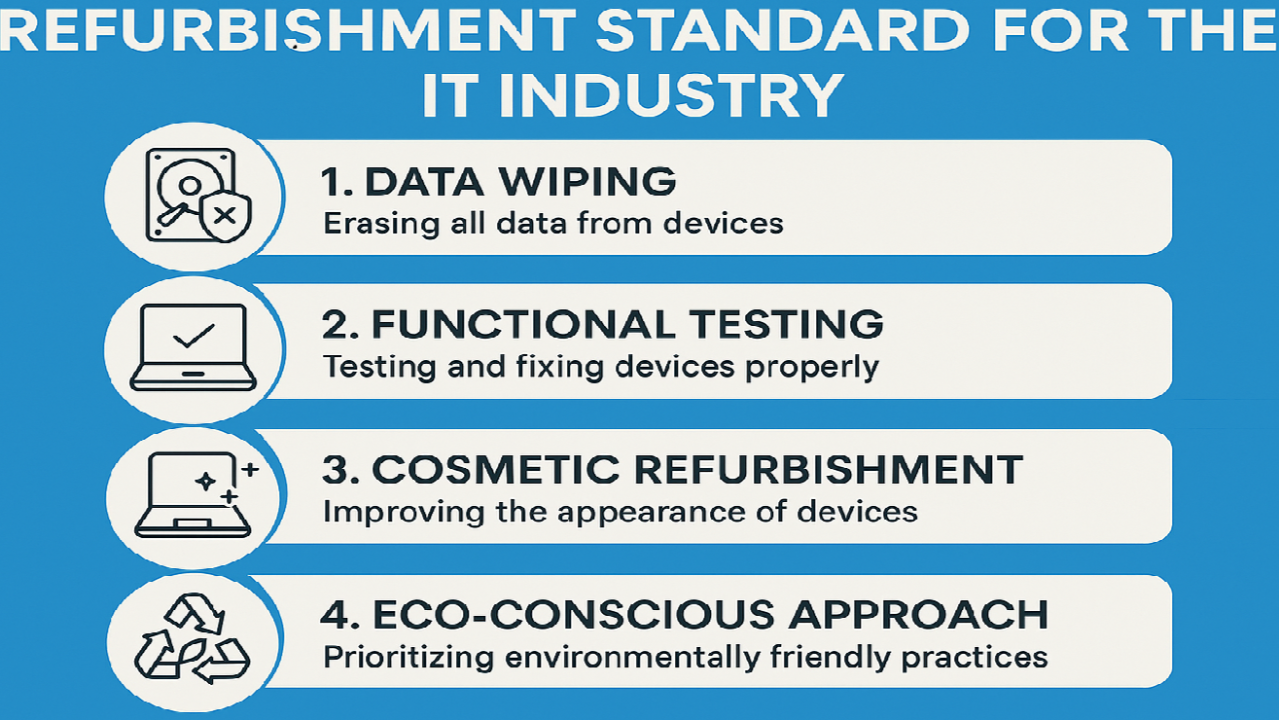

Refurbishment Standard for IT Equipment

Based on practices developed since 2005 by Leon Lindblad

1. Data Wiping

1.1 Secure Data Erasure

- All data must be erased using industry-certified tools (e.g., Aiken, Blancco, DBAN, or software compliant with NIST 800-88 standards).

- Devices must undergo at least one complete overwrite for HDDs and SSDs. When available, hardware-based secure erase should be used.

- Drives that cannot be wiped must be physically destroyed or shredded, with destruction documented.

2. Functional Testing

2.1 Hardware Diagnostics

- All devices must undergo thorough testing using automated diagnostic tools. Aiken Workbench is strongly recommended for its robust testing protocols and integrated audit trail, which logs the testing history of each device and engineer.

- Aiken Workbench can also reload operating systems on both MacBooks and Windows laptops and includes a certified data-wiping module. It is cost-effective, offering a flat monthly fee rather than a per-device charge.

- Simply powering on a device and performing data wiping does not qualify as refurbishment testing. In our experience at previous companies, this approach resulted in a 30–50% failure rate. These failures often involved minor issues, such as mismatched memory or faulty webcams and speakers, but were unacceptable for resale, as they erode trust and increase return rates.

- Diagnostic checks must include:

2.2 Component Repairs and Replacements

- Faulty parts must be replaced with OEM or equivalent-quality components.

- Batteries with less than 70% health or excessive cycle counts must be replaced. A minimum of 80% battery health is required for Grade A classification.

- Logic board issues should be assessed for cost-effective repair.

- All repairs must comply with safety standards, and ESD protection protocols must be strictly followed.

- Power supplies and power cables must be clean and in excellent condition. PAT testing (as required in the UK) must be completed for all power supplies and cables. PAT labels must clearly identify the refurbishing company.

- Power cables should be clean, neatly coiled, and securely bound—not loosely packed. The cosmetic condition of the power supply must match the quality of the device itself.

2.3 Maximisation of Stock and Parts Harvesting

- Maximising yield from incoming stock is a critical component of the refurbishment process. Past refurbishment operations we have run have achieved 95%–97% usability from bulk stock by systematically salvaging usable parts from faulty units.

- For example, if 20 out of 100 laptops in a batch were faulty, 16–18 of those were often recoverable by swapping screens, motherboards, or I/O ports between units.

- The same process applied to keyboards: by combining units with missing or damaged keys, up to 99% functional keyboards could be reconstructed. This could be complemented with keyboard printing or the application of SticKeys to complete the refurbishment.

- This approach reduces e-waste, improves sustainability, and significantly increases the return on investment for each batch of devices.

- If there are leftover laptops that cannot be repaired, any working components should be harvested and stored for future use in refurbishing the next batch. This ensures that every possible component is utilised and further reduces unnecessary waste.

3. Operating System Reload

- Only legally licensed operating systems or authorized open-source alternatives should be used.

- The OS must be reinstalled with all necessary drivers, firmware updates, and manufacturer-recommended patches.

- Post-installation validation and activation are required.

- Unnecessary software (bloatware) must be removed; only essential, user-relevant applications should be pre-installed.

- The end user must receive a device that is clean, fully functional, and ready for immediate use—enhancing customer satisfaction and brand trust.

- Once the operating system is loaded the unit must be tested with the OS before sealing it for out of box experience. This should be the final test before shipment.

4. Cosmetic Refurbishment

4.1 External Cleaning and Detailing

- Use non-abrasive, anti-static cleaners to thoroughly clean all surfaces.

- Screens must be free of smudges, scratches, and delamination.

- Keyboards, vents, and crevices must be thoroughly cleaned of dust and debris.

4.2 Refurbishment Cosmetics

- Devices must be brought to Grade A condition by applying Skins, SticKeys, Screen Savers, or using professional-grade painting where appropriate. Achieving Grade A status for all refurbished units is essential to ensure a consistent customer experience and build buyer confidence. It also simplifies stocking, inventory management, and the sales process.

- If painting is used, it must be carried out in a certified spray facility using a properly applied, durable paint layer. This ensures that the coating does not peel or wear off prematurely and must be demonstrable to an auditor.

- All applied Skins, SticKeys, and Screen Savers must come with a minimum three-year warranty covering peeling, fading, or adhesive failure.

4.3 Housing and Part Restoration

- Worn or damaged external parts must be replaced or refurbished using certified components.

- Skins or casing modifications must be applied with professional accuracy and should be reversible if required.

5. Environmental and Ethical Standards

5.1 Sustainable Sourcing

- Prioritize the reuse of components and procure from environmentally responsible suppliers whenever possible.

- All e-waste must be disposed of through certified recycling programs.

5.2 Energy Efficiency

- Devices must be tested and configured for optimal energy efficiency.

- BIOS/UEFI settings should be pre-configured to support power-saving modes.

5.3 Carbon Awareness

- Incorporate carbon offset programs such as tree planting or renewable energy contributions into refurbishment workflows.

- Minimize logistics emissions by consolidating deliveries and utilizing local refurbishment centers.

5.4 Partnering with Eco-Conscious Organizations

- Collaborate with suppliers and logistics partners that hold verified environmental certifications (e.g., ISO 14001).

- Maintain transparency in sourcing and conduct annual sustainability audits.

6. Certification and Labeling

- Each refurbished device must include a Refurbishment Certificate specifying:

- Refurbishment date

- Testing summary

- Operating system license status

- Cosmetic grade

- warranty on laptop (minimum 1 year) battery must be included in warranty

- Refurbishment location (to support low-carbon logistics)

- carbon used in the refurbishment process

- A QR code linking to an online verification portal must be affixed to each unit.